Optimize Your Production Flow

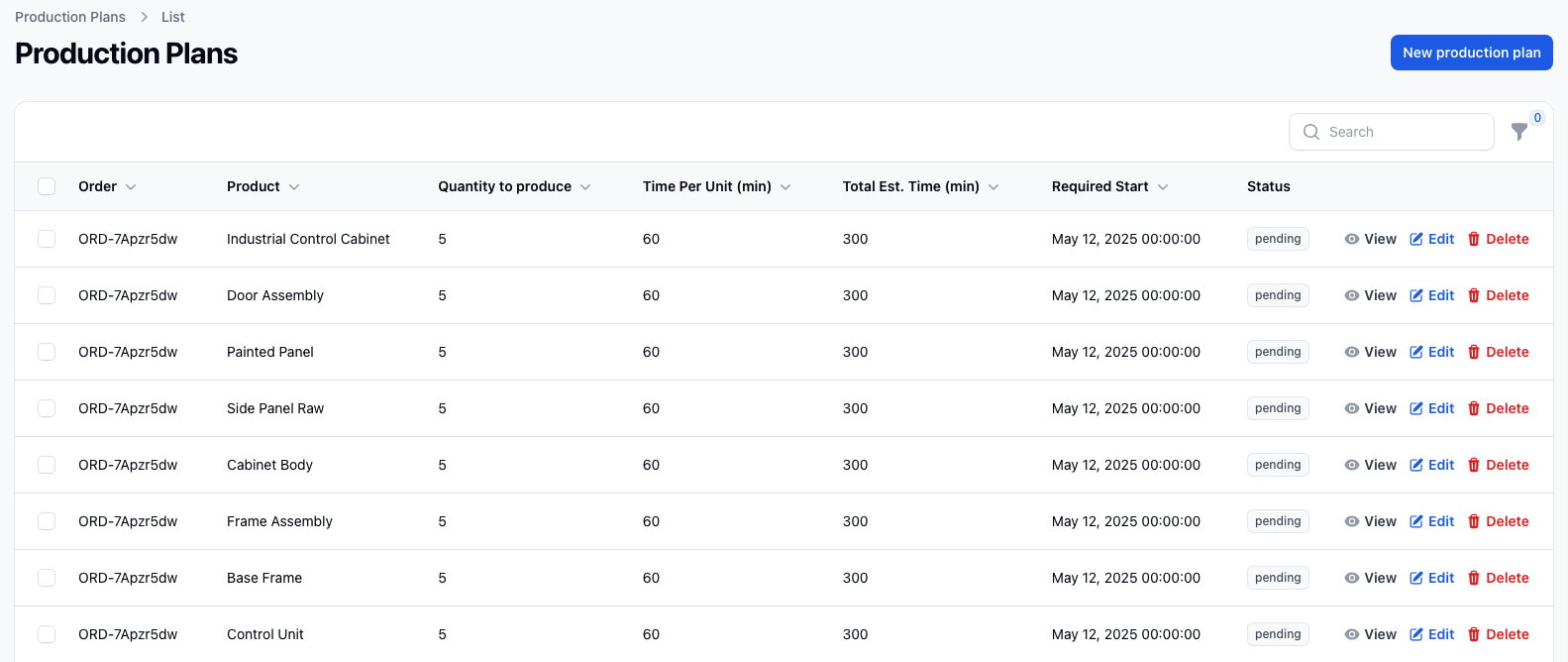

Sequence your orders most efficiently with the Production Planning module, utilize your resources at maximum capacity, and enable your operators to enter production data instantly.

Smart Planning and Operator Interaction

The system creates the most efficient production sequence based on machine, mold, and personnel availability. Operators easily enter production quantities, downtimes, and quality data via user-friendly screens.

- ✓Automatic Optimization: Optimize your production plans with a single click.

- ✓Operator Panel: Collect real-time and accurate data from the production floor.

- ✓Visual Gantt Chart: Easily manage your plans on a timeline with drag-and-drop functionality.

Integrated with Inventory, Sales, and Maintenance Modules

Production plans work in sync with real-time inventory levels and incoming customer orders. Scheduled machine maintenance is automatically reflected in the production calendar.

Key Features

Capacity Management

Identify bottlenecks in advance by defining your work center and machine capacities.

Real-Time Production Tracking

Instantly compare planned versus actual production quantities and see deviations immediately.

Material Requirements Planning (MRP)

Automatically determine the required raw materials and semi-finished goods based on your production plan.

OEE Reporting

Measure the Overall Equipment Effectiveness (OEE) performance of your machines and lines based on operator inputs.

Frequently Asked Questions

On which devices does the operator panel work?

The operator panel is web-based and easily accessible from any tablet, industrial PC, or computer on the production floor.

What criteria does the planning optimization use?

The optimization engine creates the best plan based on multiple criteria such as delivery date, setup times, machine efficiency, and raw material availability.

How can I include an urgent order in the plan?

You can easily include it by prioritizing urgent orders on the Gantt chart or by re-optimizing the current plan instantly.

All Modules, As They Should Be

Each of our modules is meticulously designed to maximize your efficiency. To maintain our quality standards, we even automate our testing processes.

Everything in harmony.

The actions of all modules in one place.