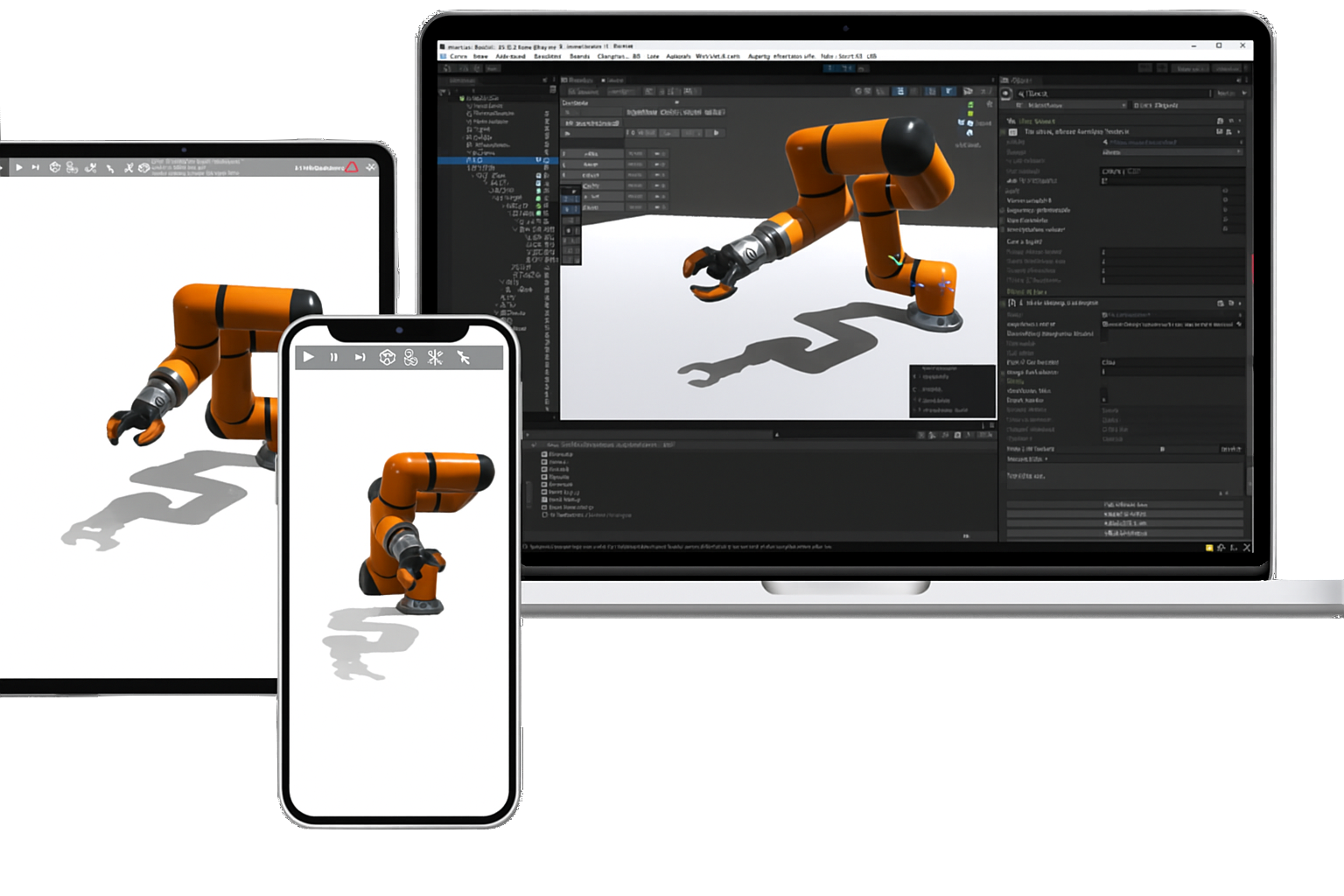

From Idea to Digital Twin.

Aydex Systems offers a revolutionary digital twin and simulation service for your industrial automation projects. Reduce costs, increase efficiency, and eliminate risks by testing your systems in a virtual environment before physical installation.

Full Compatibility with Your Existing Systems.

Easily import your standard CAD files like STEP, FBX, and your PLC programs like Siemens S7, Beckhoff into the platform. Perform virtual commissioning and testing without the need for physical prototypes.

- ✓Reduce hardware costs.

- ✓Shorten project delivery times.

- ✓Minimize programming errors.

Access Anywhere, Collaborate Together.

Your simulations are secure in the cloud. Whether you're in the office or on-site, access your projects from your Windows, macOS, or Linux devices and collaborate with your team in real-time.

Detailed and Control

The simulation allows you to precisely analyze the assembly process of each part, its motion paths, and potential collision points. This eliminates the costs of physical prototypes and significantly shortens the commissioning time.

- ✓Cycle time optimization

- ✓Verification of robot programs

- ✓Reachability tests

Have a Question?

What is a digital twin simulation for?

A digital twin is a virtual copy of a physical production line or machine. With our service, you can test your automation systems, perform efficiency analyses, and identify potential problems in a virtual environment before real-world installation. This reduces your investment costs and speeds up the commissioning process.

Why is this service necessary?

Virtual testing before physical installation prevents expensive hardware failures, production downtimes, and inefficiencies. Our simulation service reduces project risk, allows you to explore best-case scenarios, and maximizes your return on investment (ROI). In short, it enables you to make smarter, safer decisions.

Can we test our PLC program in this simulation?

Absolutely. This is one of the most important parts of the service we offer. You can run your developed PLC code on the digital twin we create to verify logical errors, sensor-actuator interactions, and system behavior in real-time. This is known as "virtual commissioning" and can reduce on-site commissioning time from weeks to days.

Do we use the simulation ourselves?

No, this is a "Simulation-as-a-Service" model. You share your project details and PLC code with us, and our expert team creates the digital twin, performs the tests, and presents the results to you in a detailed report. This eliminates the need for expensive software licenses or specialized personnel.